About Butler Manufacturing™

For nearly 120 years, the name Butler Manufacturing has been synonymous with building and construction innovation. We pioneered the start of the global metal building industry in 1901 when we challenged the status quo.

Today, we are an extremely versatile and experienced multi-million dollar company focused on providing high-quality commercial and industrial metal building systems that continue to break the mold.

The Butler Difference

We create buildings that do more. From proven building quality to leading design services, we are known for providing better building solutions.

The Butler Builder® Network

We know that a successful building project is about more than the result. With the Butler Builder Network, we deliver quality buildings, constructed efficiently with a team that has your best interests in mind. You work directly with a proven expert throughout the entire project, so we can mitigate challenges and collaborate with you on solutions.

Take pride in your work. It’s an old-fashioned value, but it’s at the heart of what we do. That’s why we don’t let just anyone construct a Butler building.

Industry-Leading Design Capabilities

We offer modern and flexible design options for all of our metal building systems. Using advanced construction technologies and industry expertise, we create better answers for building design requirements through new products, new technology, and customized building designs.

Proven Building Quality

The difference is in the details, from the Scrubolt™ fasteners to the roof clips. Butler building components are designed for strength, durability, longevity and sustainability. We’re so confident in what we build, we offer the industry’s leading warranties.

Built-In Lifetime Savings

Up to 90 percent of a building’s total cost is incurred after construction, so the decisions made during the building design phase will have a major impact on your annual operating costs. Focusing on options that offer energy efficiency and long life spans will help you minimize your total cost of ownership. Our building assemblies are tested and proven to be more energy-efficient than industry standards, and our buildings are engineered and built to last with virtually no upkeep.

Single Point of Contact on Multisite Projects

Whether you’re building multiple projects across North America or around the world, you’ll have a single point of contact who removes project limitations with a collaborative approach.

Research and Development That Create Innovations

We constantly push the boundaries to find better answers to building challenges. Our innovations help you build better, through more flexible and durable building systems and technology that streamline the building process.

Nearly 120 Years of Expertise

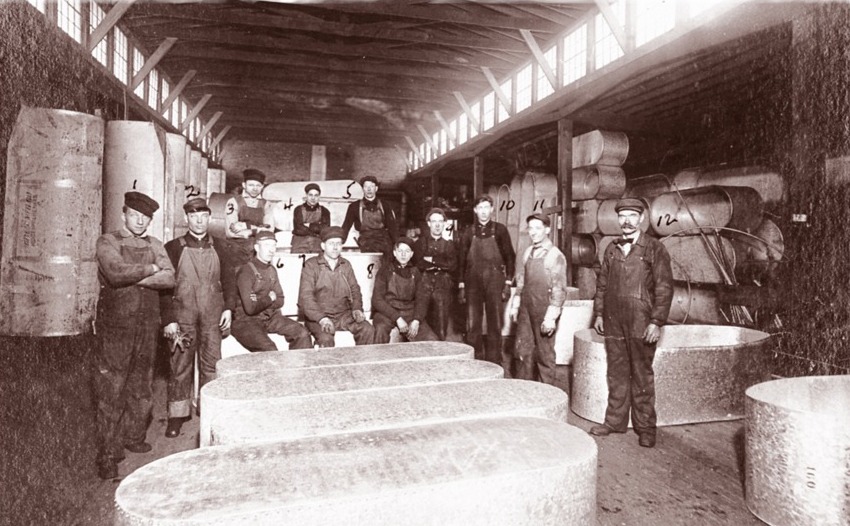

No one has been in this business as long as we have. We pioneered the metal building industry in 1901 and have continued to modernize it with major product and process innovations. With this solid foundation, we can handle any building challenge.

Associations and Certifications

- U.S. Green Building Council (member)

- Metal Building Manufacturers Association (founding and current member)

- International Accreditation Service (accreditation demonstrating our organization operates at the highest level of ethical, legal and technical standards)

- FM-approved (signifying our products and services will perform as expected to support property loss prevention)

- UL-registered

Built By Hand, Backed By Experience

HUMBLE BEGINNINGS

THE FIRST BUTLER® BUILDING

THE GREAT GRAIN BIN ADVENTURE

RIGID FRAME INNOVATIONS

EXPANDING OPPORTUNITIES

MAKING INDUSTRY HISTORY

A NEW BEGINNING

With the acquisition of Butler Manufacturing Company, BlueScope Steel is now the leader in pre-engineered buildings in North America and China and is No. 1 in premium steel building products in China.

FOCUSED ON THE FUTURE

Our team actively seeks out ways to advance and grow alongside the ever-changing steel industry. We are dedicated to innovating and investing in new technologies that streamline the building process and create more effective and efficient solutions for our clients for centuries to come.

Find a Butler Builder®

Search our expert network of Butler Builders throughout North America