Project Details

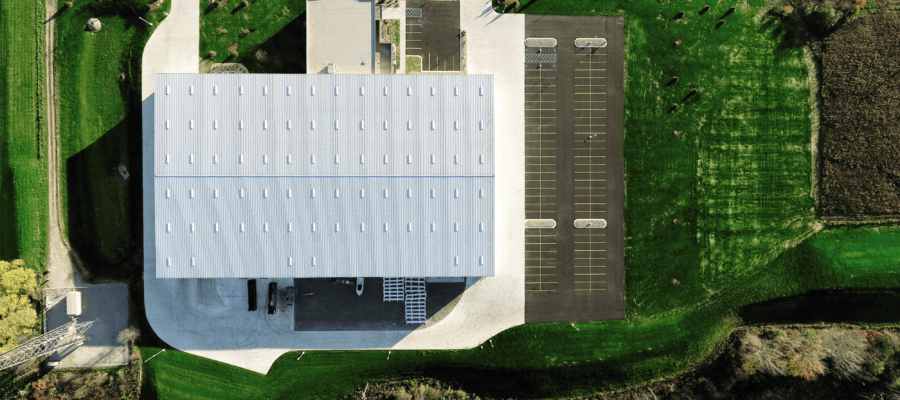

Successful manufacturer attracts five applicants per day with help of new building.

Massive Muscle: The building offers more functionality than the company’s competitors, which helps drive business.

Curb Appeal: A high-quality work environment helps draw in a steady stream of applicants.

Health First: Daylighting, filtered water and other health-focused amenities help keep employees productive.

What do you do after selling your booming industrial business to Berkshire Hathaway? Well, if you’re Tom Miller and his children, Chad, Michael and Matt Miller and Jennifer Sage, you get to work building up another company.

For 30 years, the Millers’ efforts centered on a custom air handling and hydronics manufacturer just outside of Flint, Michigan. In 2014, the family bought out metalworking and welding company Performance Fabricating. At the time, they planned to apply the same approach they used with their first entrepreneurial endeavor: provide premium quality products and treat employees like family.

With the purchase of the business, the Millers also acquired its 20,000-square-foot manufacturing facility in nearby Fenton, Michigan. But to achieve the amount and type of growth the Millers sought, and to attract the talent needed to fuel the growth, it became clear the business needed a new headquarters.

“Aesthetics is everything. When our customers come to see how the product is made, the first thing they see is the building. We wanted a bright, well-lit, good working environment for our team and to demonstrate to our customers the level of quality they’ll get by working with us.”

Chad Miller, Performance Fabricating

The Millers paired with Kevin Johnson and his firm Rhoads & Johnson, a Butler Builder® to create the building that would help build their business. As another local, long-standing family-owned operation, Rhoads & Johnson offers an in-depth understanding of the Fenton business climate and how building design decisions can impact company success. From the beginning, it was a trusted collaboration.

“When Kevin does work for you, he puts his heart and soul in it, and you can see it in everything Kevin does.”

Chad Miller, Performance Fabricating

As a Butler Builder, Rhoads & Johnson also provides best-in-class materials, so the building meets the needs of a top-tier manufacturer.

First and foremost, to deliver on the Millers’ business plan, the building needed enough muscle to handle the company’s massive outputs. Performance Fabricating supplies major automotive companies and others with metal products such as steel platforms, mezzanines, stairs, handrails and automation conveyors. To be effective, the manufacturing space must accommodate 65 tons of highbay cranes, which allow technicians to easily assemble these large pieces of equipment and fulfill customer requests for custom extra-large products when their competitors can’t.

“Nobody in the area has a facility like this with 80-foot bays and 10-ton cranes. We then have 23 to 26 feet underneath our cranes. It’s what sets us apart.”

Chad Miller, Performance Fabricating

Another point of differentiation is all Performance Fabricating products are powder-coated. To keep operations efficient, the Millers brought the powder-coating line in-house in the new facility. They had been shipping products two hours away. The process includes two 40-by-15-by-15-foot ovens, some of the largest in the area. It was imperative the building design use a minimal number of interior columns to house the large equipment and allow product to be moved through the building with ease.

The Widespan™ structural system was an ideal solution for each of the business’s requirements. As the workhorse of the Butler structural system lineup, it combines the practicality of a rigid frame with virtually unlimited design flexibility. Its modular framing systems are designed to minimize the number of interior columns and are available in widths from 60 to 300 feet with interior modules from 20 to 80 feet. The acrylic-coated, galvanized C/Z structural members add durability and reduce maintenance.

At the heart of the Millers’ businesses are their people, and keeping the employees central when making building decisions helps the company attract and retain key talent, despite a manufacturing labor shortage.

“As the automotive industry in this area continues to ramp up, attracting labor is a huge issue right now. Having a great place to work is a huge benefit.”

Kevin Johnson, Rhoads & Johnson

One key element is the building’s curb appeal. Unlike other facilities in the area, the Millers’ new structure features an inviting design and modern office space with a curved exterior wall and high ceilings.

“Not only did the Millers update their building design, but also they’re changing the perception of the industry.”

Kevin Johnson, Rhoads & Johnson

The new Performance Fabricating facility certainly speaks to the business’s people-first culture. Unlike traditional welding shops, it is clean and bright. The SunLite Strip® daylighting system from Butler allows natural light to fill the manufacturing space throughout the day, without glares or hot spots. Additionally, thoughtful HVAC design filters the air in the shop to keep clean air flowing throughout the day. The air is warm in the winter and cool in the summer, so employees work at a comfortable 65 to 70 degrees each day.

The Millers also opted for additional features to help keep employees healthy. Employees can sip on reverse-osmosis-filtered drinking water and no longer need to lug large tanks of gas or compressed air to their workstations. Both of these factors help reduce the chances for injury and illness. The manufacturing floor offers hookups for weld gas and compressed air drops throughout.

The layout includes space for employees to relax. The break area features a soda fountain and an 80-inch TV where employees can be found catching a Detroit Tigers game over lunch.

“People are here a big portion of their day, and they want to enjoy where they are.”

Chad Miller, Performance Fabricating

The investment was well worth it. Today about five people a day come in to fill out an employment application.

Welding is energy-intensive, so the Millers focused on maximizing efficiency everywhere they could. The full building features LED lighting controlled by motion sensors.

Additionally, the Butler Thermawall™ wall system ensures the energy spent heating and cooling the 106,000-square-foot building does not go to waste. This factory-insulated wall panel can feature up to 4 inches of foam insulation to achieve an R-value up to R-29. The SunLite Strip daylighting system also provides significant energy savings by reducing the amount of light needed to illuminate the building throughout the day.

Instead of focusing solely on construction costs when making building-design decisions, the Millers kept their future needs in mind.

“A lot of times people just look at the overall cost of the building, and sometimes just going a little bit larger is not as much money during construction as it would be after. You’re better off doing it now than planning to add on later.”

Chad Miller, Performance Fabricating

With this approach, the Millers decided to bump up their facility footprint. Additionally, their building’s structural and wall systems will help minimize costs should it need to be expanded later. A benefit of Butler building systems is how they can be expanded with ease.

Because the Millers’ ability to grow their new business centered on the new facility, getting the building up and running as quickly as possible was crucial.

“We put the footing in the ground in February, and we moved into the shop in August. That’s not messing around. Kevin has good subs, good suppliers, and when he asks them to do something, they do it, and they move fast. To have us in the shop in six months or just under was great.”

Chad Miller, Performance Fabricating

Together, the Millers and Rhoads & Johnson, along with architect John Asselin Jr. of Asselin, Mclane Architectural Group, created a place that is not only changing the face of an industry, but changing a community as well.

In the six months after the project was completed, the business added more than 60 jobs, nearly tripling in size.

“This is the largest building in the Fenton township. I’m proud to bring this work to this area for these people. It’s good for our township. It’s good for Fenton. It’s good for this area.”

Chad Miller, Performance Fabricating

SunLite Strip® has been further enhanced since this project was completed.

Rhoads & Johnson

rhoadsjohnson.com

Asselin Mclane Architectural Group

Connect with us for details about how we can solve your specific wall system needs.

© 2024 BlueScope Buildings North America, Inc. All rights reserved. Butler Manufacturing™ is a division of BlueScope Buildings North America, Inc.