A newly formed, innovative team is capitalizing on their individual strengths to take a quantum leap forward in construction speed and efficiency. They are doing so – not by thinking outside the box – but by thinking of the box inside the box.

You might call it the “podification” of unit operations or entire processes, and at least for one very large and growing industry, the implications are enormous.

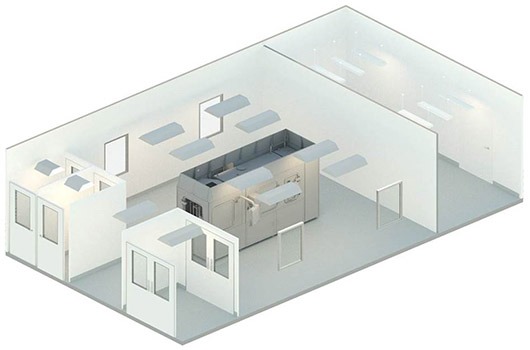

Picture a weathertight, energy- and maintenance-efficient “containment vessel” (shell structure) that houses multiple, innovative PODs® (prefabricated, autonomous cleanrooms). These PODs of varying sizes are self-enclosed, or can be docked or clustered together within the building for increased unit-to-unit process efficiency.

Sound like something from a sci-fi novel? Perhaps. But it’s already being done, and it’s about to revolutionize pharmaceutical and biopharmaceutical manufacturing facility construction and deployment.

Imagine cutting a year or more off aggressive design and construction schedules.

For pharma, biopharma and cell therapy companies, (and many other highly regulated, high-tech manufacturing processes) gaining a year or more in facility construction time is extremely valuable.

Considering that most drug product patents are granted for 20 years, with the actual commercialization being a much shorter timeframe, the exclusive annual sales of a breakthrough drug is conservatively a multi-million dollar amount. Lost time is lost revenue that can never be recovered. The benefit is crystal clear.

It takes three to transform the norm.

The new collaboration brings together three industry leaders in their respective fields with unique capabilities.

Butler Manufacturing™ is a well-established global provider of design-build, engineered systems and technology, which enable faster erection schedules and employ proven and tested building solutions that can drastically reduce total facility cost of ownership.

Span Construction is a design-build General Contractor specializing in commercial steel building structures that provides advanced engineering and completion quality. The company has decades of experience in constructing a variety of impressive buildings amounting to a total of over 150 million square feet since 1979.

Working in precise collaboration, the building shell structure is erected concurrently with the POD units, so absolutely no time is wasted. Rather, the schedule is substantially condensed by this well-coordinated, systematic, turnkey approach.