Why Butler

- There are more than 1,000 Butler Builders across North America. Logistics facilities require special considerations, such as location, land availability, and labor force. Wherever you choose to build, we have a local builder ready to assist you. Our builders are known for their commitment to quality and they are experts in local construction knowledge with crews ready to build for you.

- We use just-in-time manufacturing techniques to synchronize the fabrication and delivery of materials to match the sequencing of the project. We understand time is money, and we want to design and deliver the building you expect while meeting the timeline you need.

- Butler provides construction planning tools including apps to track materials from the factory to the job site and electronic drawings that allow erectors to work more efficiently. This approach reduces the loss of materials, provides increased job-site space for better safety, and significantly improves the speed of construction.

“When you choose Butler and work with a Butler Builder®, you get an integrated team focused on the success of your project and your business,” said Steven Hudgins, vice president of sales for Butler Manufacturing. “We are focused on finding the best solutions for you and delivering on them. The multiple capabilities we have drive excellence and efficiency for your project. We do not believe it is an either/or situation. You deserve both, and with Butler, you will get both – and more.”

How Butler Does It

There are several Butler products designed to help your logistics center achieve supply chain excellence.

- The MR-24® roof system is the best performing commercial roofing system available. With proven, in-place performance for over 50 years, the MR-24 roof system provides substantially lower cost of ownership when compared to other types of systems. As the industry’s first and finest standing-seam metal roof system, the MR-24 is the best roof for protecting critical business inventory.

- Butler products provide maximum flexibility while simplifying the supply chain. We can provide you with both pre-engineered and conventionally designed building systems, or a hybrid combination of the two methods.

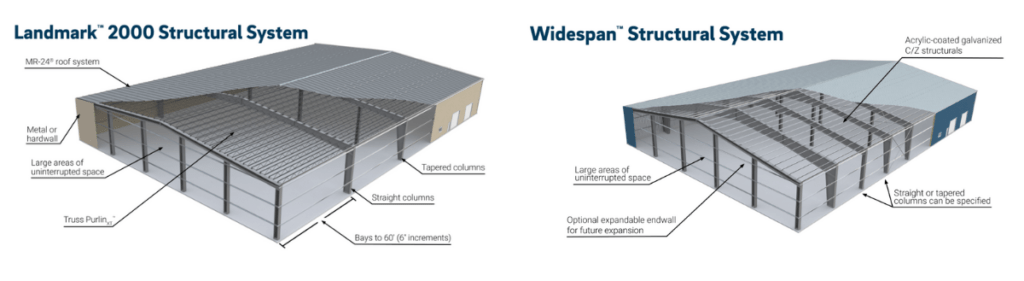

- The Widespan™ structural system combines the practicality of a rigid frame with virtually unlimited design flexibility. This system easily facilitates expansions or extensions. The minimal columns and uninterrupted space provided by the Widespan system makes it an excellent option for logistics facilities. It provides plenty of space for racking with space left-over for easy maneuverability of forklifts and other important equipment.

- The Landmark™ 2000 structural system is a long bay framing system that can span up to 60 feet. This is an economic design solution for buildings that require wide-open interior space. This structural system option can accommodate complex conveyor systems and sorting equipment easily.

Designed to Optimize

- Both the Widespan and Landmark structural systems can be designed to incorporate dedicated areas for your employees to efficiently pick, pack, and kit orders.

- Whether you need to manage seasonal surges, special fulfillment processes, or end-to-end reverse logistics for merchandise returns, we design your facility to support critical business operations.

- If advanced automation, robotics, and sensors are part of your logistics plan, we have you covered. Our goal is to build a facility that stands up to your needs today while meeting the technology of tomorrow.

Achieving Supply Chain Excellence

Brownells identifies itself as “the world’s leading source” for gun parts, accessories, and ammunition. After years of growth, which included the acquisition of several other brands, the company needed to rethink its distribution strategy.

While they had successfully transitioned from paper catalog sales to e-commerce, Brownells saw an opportunity to offer their customers a brick-and-mortar store location. They also saw the opportunity to update and expand their distribution center to better serve customer demand for the 90,000 parts, tools, and supplies they sell.

Brownells partnered with Septagon, a Butler Builder, for the project which resulted in a completed 7,000-square-foot retail showroom and a 200,000-square-foot state-of-the-art warehouse and distribution center in Grinnell, Iowa. The facility uses the Landmark™ 2000 structural system, the MR-24® roof system, and the Shadowall™ wall system. It includes a mezzanine, as well as a 3-story pick line. Scanners, color-coded tubs, and conveyor belts are used to sort inventory.

A third-generation family business, Brownells prides itself on quality, consistency, and customer service – three critical elements of supply chain excellence.

When it comes to a logistics facility, what do you need – high racks, multiple docks, uninterrupted interior space? A Butler building helps position you for excellence in freight and distribution with a facility designed to meet current and evolving business needs.