When Marius Rygg first saw a mock-up of the Express Mezz™ System, he knew his company needed to try it. A construction veteran with more than 30 years working directly with Butler Manufacturing™ and their products, Rygg knows the importance of innovation.

For the past several years, he has led the Mankato, Minnesota and Fargo, North Dakota locations of Rice Companies, a third-generation, family-owned general contractor with four locations in Minnesota and North Dakota. Rice has been a Butler Builder® for nearly seven decades. So, it made sense that they would be the first to roll out the new Butler Express Mezz System, an inventive and cost-effective solution to mezzanine construction.

They quickly saw the opportunity with a project for an established customer, Rihm Kenworth, a truck sales and service business specializing in semi-trucks and tractors. The project involved remodeling an existing building for office workers and parts, then constructing an entirely new truck shop.

It was in that new structure (which also happened to be a Butler building) that Rihm Kenworth needed a mezzanine system to store fuel tanks, oil, air compressors, and other equipment and truck parts. Other Rihm Kenworth locations utilized a similar setup and leadership in the Albert Lea, Minnesota shop wanted to introduce a comparable functionality and feel.

Speed, Cost, & Simplicity

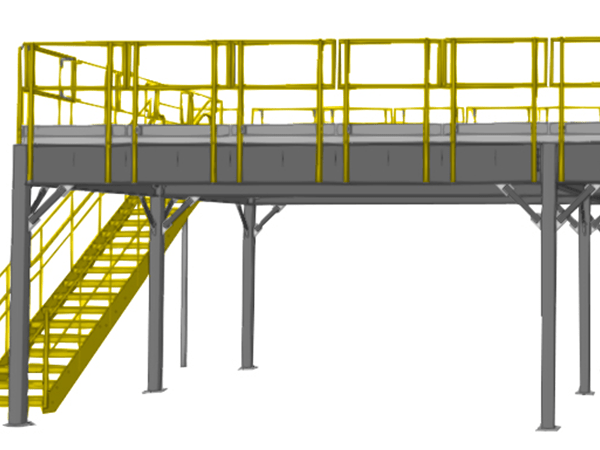

With 120 years of metal building construction under our belts, it’s safe to say that the team at Butler knows a thing or two about innovation. It was that desire to imagine quality products that are versatile, cost-effective, and a better alternative to the existing solution that led to the concept and development of the Express Mezz System.

“For the customer, they can get immediate additional storage space without having to modify their existing building,” said Carl Walker, strategic project manager with BlueScope Buildings North America, and one of the team members who helped design the Express Mezz System. “With this freestanding product, it’s easy and fast,” he said.

Adding the Express Mezz System is a simple solution to the problems that have plagued mezzanine construction for years. Rather than ordering a mezzanine from someone else, a customer can work with their builder to request the Express Mezz System and have it configured to their specifications and engineered and constructed in a way that will last.

“If I have a warehouse and need an additional 5,000 square feet, I don’t have to wait around for building analysis or think about all the possible problems that might come up with building something new,” Walker said. “If the building is tall enough and I can put this second floor in, I can go to Butler, and the Butler Builder can provide me with the Express Mezz System quickly,” he said.

Effective Design & Convenient Options

- In terms of size, there are standard module dimensions beginning at 8’ x 8’ and up to as large as 28’ x 28’ in four-foot increments.

- There are two standard heights with 9’ or 10’ clearance from the underside of perimeter beams provide plenty of space beneath the mezzanine for business to continue as usual.

- Six different economical floor surface options are available with the Express Mezz System. Among the choices, customers can select from ResinDek® options that feature pallet jack ratings up to 2,800 pounds, one 4” cast-in-place concrete option, and a 3/4” board option.

Marvel At The Mezzanine

In projects like what Rice Companies completed for Rihm Kenworth—jobs that involve standing-up much larger structures—the inclusion of an affordable and easy-to-assemble mezzanine might seem insignificant. But in some cases, saving the customer a few thousand dollars and hours of stress can change the complexion of a project.

The Express Mezz System arrived on-site complete. With a simple erection process and no welding needing, the system was quickly bolted together without any snags as Rice Companies’ workers could easily read and understand the product’s prints.

According to Rygg, the experience was significantly better than other mezzanine projects that Rice Companies has completed in tandem with local structural steel fabricator shops and mezzanine manufacturing outfits, which were all more cumbersome to assemble and higher in price. The project was finalized with no missed deadlines or budget surprises.

After the installation was complete, Butler’s Carl Walker visited with Rygg and the team at Rice Companies to get their reaction to the process and hear what it was like working with the first-ever Express Mezz System. He also took pictures of opportunities for improvement in future versions of the product.

“After they installed it, I sat down and talked with them for about an hour,” Walker said. “They were very pleased with it and how well it went together. They didn’t have to drill or add one hole, and the general reception was, ‘Nice product. I’d order it again,’” he said.

A Commitment To Perfection

Armed with feedback on a few different areas, Walker returned to work with ideas for enhancements on the Express Mezz System. Specifically, the Butler Innovation Group is exploring additional shape options and reaching into higher seismic zones. That type of commitment to continually iterating and refining products to perfection is part of why builders want to work with Butler and why those builders recommend Butler products to their customers.

Walker, who started working on the product’s design in late 2018, said he’s excited about the future for the Express Mezz System and looks forward to helping more Butler Builders by relieving the burden that usually comes with mezzanine projects.

“We have taken away all the worries from projects like Rihm Kenworth,” Walker said. “No more do they have to think, ‘Did I get the right engineer? Did I get the right parts? Did I get the right pieces? Does it really fit together? Did the shop do it right?’ This is one-stop shopping. We do the drawings, the detailing, the engineering, and the fabrication. We try to take the stress away from the builder,” he said.

“This is like pushing the easy button,” Walker said.